Progressive cavity pumps (PCPs) are essential in industries requiring precise, consistent, and gentle fluid handling. These pumps excel in handling viscous, abrasive, and shear-sensitive fluids, making them ideal for oil & gas, wastewater treatment, food processing, and chemical industries.

This guide explains how progressive cavity pumps work, their advantages, applications, maintenance tips, and how to choose the right one for your needs.

How Does a Progressive Cavity Pump Work?

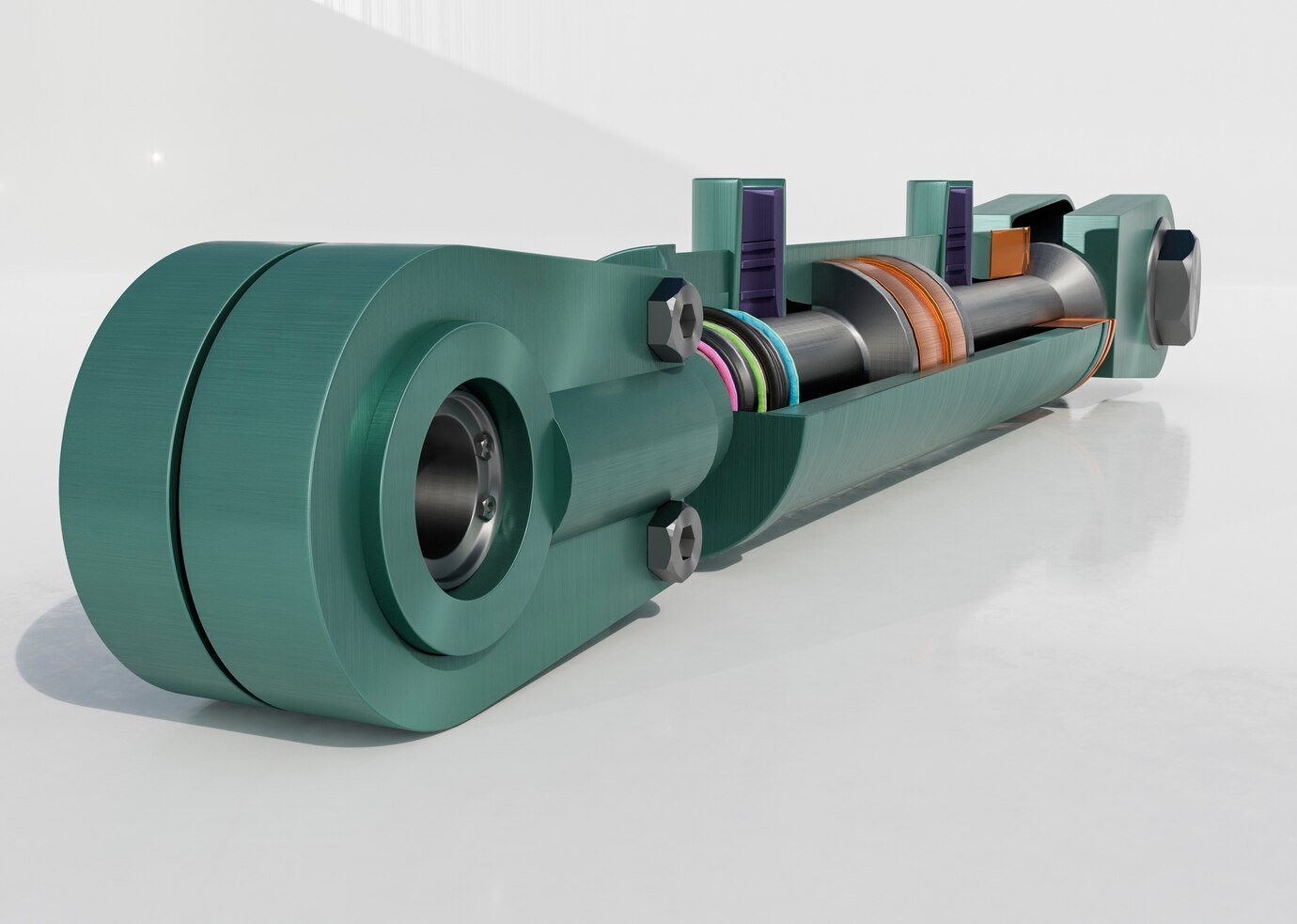

A progressive cavity pump consists of two main components:

-

Rotor – A helical, single-threaded screw made of metal or elastomer.

-

Stator – A double-threaded, rubber-lined housing that fits the rotor.

As the rotor rotates inside the stator, cavities form and progress from the suction to the discharge end, moving fluid smoothly with minimal pulsation.

Key Features of Progressive Cavity Pumps

-

High Efficiency – Maintains consistent flow rates even with varying pressures.

-

Low Shear – Gentle handling of shear-sensitive fluids (e.g., food products, polymers).

-

Self-Priming – Can handle fluids with entrained gases or solids.

-

Versatile – Works with viscous, abrasive, and corrosive fluids.

Applications of Progressive Cavity Pumps

Progressive cavity pumps are used across multiple industries due to their reliability and adaptability.

1. Oil & Gas Industry

-

Transferring crude oil, drilling mud, and viscous hydrocarbons.

-

Handling multiphase fluids (oil, water, gas mixtures).

2. Wastewater & Sludge Handling

-

Pumping thick sludge, sewage, and abrasive slurries.

-

Used in municipal and industrial wastewater plants.

3. Food & Beverage Industry

-

Gentle pumping of yogurt, chocolate, dough, and fruit pulps.

-

Hygienic designs meet FDA and EHEDG standards.

4. Chemical & Pharmaceutical Industry

-

Metering and transferring polymers, adhesives, and solvents.

-

Handling corrosive and high-purity fluids.

5. Mining & Construction

-

Dewatering, slurry transfer, and tailings management.

Advantages of Progressive Cavity Pumps

✅ Consistent Flow – No pulsation, ideal for metering applications.

✅ Handles High Viscosity – Efficient with thick fluids like honey, grease, and bitumen.

✅ Tolerates Solids – Can pump fluids with suspended particles.

✅ Energy Efficient – Lower power consumption compared to centrifugal pumps for viscous fluids.

✅ Low Maintenance – Fewer moving parts reduce wear and tear.

Disadvantages & Limitations

❌ Not Ideal for Low-Viscosity Fluids – Less efficient than centrifugal pumps for thin liquids.

❌ Sensitive to Dry Running – Can damage stator if operated without fluid.

❌ Higher Initial Cost – More expensive than some alternatives but cost-effective long-term.

How to Choose the Right Progressive Cavity Pump

1. Fluid Characteristics

-

Viscosity – PCPs work best with medium to high-viscosity fluids.

-

Abrasiveness – Hardened rotors and abrasion-resistant stators extend lifespan.

-

Corrosiveness – Stainless steel or coated rotors prevent chemical damage.

2. Flow Rate & Pressure Requirements

-

Match pump size to required flow (GPM or m³/h) and discharge pressure.

3. Material Compatibility

-

Stator Material: Nitrile, EPDM, or Viton for chemical resistance.

-

Rotor Material: Chrome-plated steel, stainless steel, or carbide-coated for durability.

4. Pump Speed & Efficiency

-

Higher speeds increase flow but may reduce stator life.

-

Variable speed drives (VSDs) optimize performance.

5. Maintenance & Serviceability

-

Choose pumps with easy rotor-stator replacement.

-

Consider seal-less designs for leak-free operation.

Maintenance Tips for Progressive Cavity Pumps

✔ Regular Inspection – Check for wear on the rotor and stator.

✔ Proper Lubrication – Ensure bearings and gearbox are well-lubricated.

✔ Avoid Dry Running – Always prime the pump before starting.

✔ Monitor Vibration & Noise – Unusual sounds indicate misalignment or wear.

✔ Replace Worn Parts – Stators degrade over time; replace them before failure.

Progressive Cavity Pump vs. Other Pump Types

| Feature | Progressive Cavity Pump | Centrifugal Pump | Gear Pump |

|---|---|---|---|

| Viscosity Handling | Excellent | Poor | Good |

| Flow Consistency | Pulsation-free | Pulsating | Moderate pulsation |

| Solids Handling | Good | Poor | Poor |

| Shear Sensitivity | Low | High | Moderate |

| Efficiency with Thick Fluids | High | Low | Medium |

Future Trends in Progressive Cavity Pumps

-

Smart Monitoring – IoT sensors for predictive maintenance.

-

Advanced Materials – Longer-lasting elastomers and coatings.

-

Energy-Efficient Designs – Improved hydraulics for lower power consumption.

Conclusion

What Is a Progressive Cavity Pump? Progressive cavity pumps offer unmatched efficiency for handling viscous, abrasive, and shear-sensitive fluids. By understanding their working principle, applications, and maintenance needs, you can maximize their performance and lifespan.

Whether in oil & gas, food processing, or wastewater treatment, choosing the right PCP ensures smooth, reliable operations. Invest in quality pumps, follow maintenance best practices, and stay updated with industry advancements for optimal results.

FAQs

Can a progressive cavity pump handle abrasive fluids?

Yes, with hardened rotors and abrasion-resistant stators, PCPs can handle slurries and abrasive liquids.

What causes stator failure in PCPs?

Dry running, excessive pressure, and chemical incompatibility degrade stator elastomers.

Are progressive cavity pumps self-priming?

Yes, they can self-prime but perform best when properly primed.

How do I know if my PCP needs maintenance?

Reduced flow, increased noise, or leaks indicate wear and require inspection.