Meta Description: Which CNC machine offers better value for your investment: a Swiss Lathe or a Router? Dive into our comprehensive guide to uncover the cost differences and determine which suits your production needs best.

When investing in machining equipment, it’s vital to understand the differences between various tools to make the right decision. The CNC Swiss Lathe and CNC Router are two powerful machines that have become staples in precision CNC services. Both are known for their ability to produce highly accurate components, but they are designed for different types of operations. Therefore, given their various capabilities and uses, it’s not surprising that their costs also differ.

But how do you determine which one is the more expensive option? In this article, we will compare the costs associated with both machines. By exploring their features, productivity, and overall value, you’ll better understand which machine might be the better investment for your specific needs and budget.

What Is a CNC Swiss Lathe?

close up image of CNC swiss lathe for precision manufacturing

The CNC Swiss Lathe is a specialized type of lathe that produces small, intricate parts with unparalleled precision. The machine was originally developed in Switzerland for the watchmaking industry and has since evolved into a crucial tool in various high-precision fields, including medical device manufacturing, aerospace, and electronics.

How It Works

The CNC Swiss Lathe operates differently from traditional lathes. In a standard lathe, the workpiece remains stationary while the cutting tools move across it. In contrast, a Swiss Lathe feeds the workpiece through a guide bushing, holding it tightly as the cutting tools perform their tasks. This setup allows the workpiece to be machined very close to the point of support, reducing deflection and enabling the production of precise and intricate parts.

One of the standout features of the CNC Swiss Lathe is its ability to conduct multiple operations in a single setup. The machine can execute turning, milling, drilling, and even threading simultaneously, thanks to its numerous axes and live tooling capabilities. This enhances productivity and ensures the machine maintains consistent accuracy, often achieving tolerances as tight as a few microns.

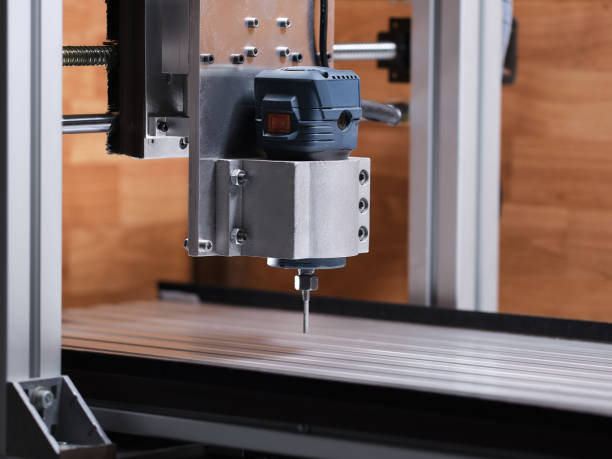

What Is a CNC Router?

table legs carving with multi heads of CNC router machine

A CNC Router is a versatile, computer-controlled cutting machine that can carve, cut, and shape various materials, including wood, plastics, metals, and composites. Unlike the CNC Swiss Lathe, which specializes in the precision turning of small parts, the CNC Router excels in handling larger workpieces and producing highly accurate complex shapes. Industries such as woodworking, metalworking, signage, and furniture manufacturing heavily rely on CNC Routers for their production processes.

How It Works

The CNC router operates on a principle similar to other CNC machines, where computer-aided design (CAD) software generates the design, and computer-aided manufacturing (CAM) software translates that design into machine code. This code instructs the router to move its cutting tools to achieve the desired shape.

A typical CNC Router consists of a work table, a spindle (the motor that drives the cutting tool), and multiple axes—usually three, but sometimes more in advanced models. The router’s spindle moves along the X, Y, and Z axes to precisely carve out intricate designs or cut through the material. The router can accommodate various cutting tools, from end mills to drill bits, allowing it to perform multiple tasks, including cutting, drilling, engraving, and milling.

Cost Considerations for CNC Swiss Lathe vs CNC Router

Check the cost considerations for both precision CNC machines below:

CNC Swiss Lathe

When considering cost, the CNC Swiss Lathe generally falls on the higher end of the spectrum. The initial investment for these machines ranges depending on the model, brand, and available axes and tooling options. However, this high upfront cost often pays off in industries where precision, speed, and reliability are crucial.

Ongoing costs, such as maintenance, tooling, and operator training, also contribute to the overall expense. Due to the machine’s complexity, operators require specialized training to utilize its capabilities, which adds to the overall cost. Despite these costs, the CNC Swiss Lathe can deliver a substantial return on investment, especially in high-volume production where precision and consistency are crucial.

CNC Router

CNC Routers generally have a lower entry cost than CNC Swiss Lathes, making them accessible to various businesses, including small workshops. Prices for CNC Routers can vary widely based on the machine’s size, capabilities, and the materials it can handle. Basic models are usually less expensive, while more advanced models with larger work areas, higher power spindles, and additional features come at a much higher price.

Beyond the initial purchase price, other costs include tooling, maintenance, and potentially upgrading the software or hardware to keep the machine performing at its best. Operators also need training, though it may not be as extensive as the training required for CNC Swiss Lathes. Similarly, the return on investment for a CNC Router can be substantial. This is because its capability to handle multiple tasks in a single setup saves time and cuts labor costs, thus making it a cost-effective choice for many businesses.

Here’s a concise comparison table for the CNC Swiss Lathe and CNC Router highlighting the cost considerations:

| Aspect | CNC Swiss Lathe | CNC Router |

| Machine initial cost | High, as it ranges from $150,000 up to $500,000 or more, depending on the model | Less than CNC Swiss Lathe as it ranges from $50,000 to $150,000+, also depending on the model |

| Ongoing Costs | Maintenance, tooling, operator training | Tooling, maintenance, software/hardware upgrades |

| Training Requirements | Specialized and extensive | Basic to moderate |

| Return on Investment | Significant in high-volume production | Substantial in versatile application |

| Precision | High | Moderate to High |

CNC Swiss Lathe vs CNC Router: Which One Is Better in Productivity?

precision metal components made with CNC machines for industrial applications

When comparing the productivity of a CNC Swiss Lathe vs a CNC Router, it’s essential to understand that productivity can vary greatly depending on the specific application, the type of workpiece, and the required level of precision.

Check the details on the productivity of both machines below:

Productivity of a CNC Swiss Lathe

The CNC Swiss Lathe shines in tasks where precision and small-part production are paramount. One of the key factors contributing to the CNC Swiss Lathe’s productivity is its multi-axis capability. With the ability to work on multiple axes simultaneously, the machine can execute complex machining tasks without repositioning the workpiece. In a high-volume production, the CNC Swiss Lathe can produce thousands of identical parts with minimal variation, ensuring that each piece meets the required specifications without requiring extensive quality checks or rework.

However, the CNC Swiss Lathe’s focus on precision and complexity also means that it may not be the fastest option for simpler tasks. If your production needs involve larger parts or less intricate designs, the time and effort required to set up and run a Swiss Lathe might outweigh the benefits. Additionally, the machine’s complexity often necessitates specialized training for operators, which could slow down productivity during the initial stages of operation.

Productivity of a CNC Router

On the other hand, the CNC Router excels in scenarios where versatility and the ability to handle larger workpieces are key. Its design allows for rapid material removal and the ability to cut, carve, and shape a wide range of materials with relative ease. The CNC Router’s capacity to switch between different tools automatically during a job enhances its productivity. For instance, in woodworking, a CNC Router can cut the main shape of a piece, switch to a different tool to carve intricate details, and then drill holes—all in a single setup. This, in turn, increases overall output. In addition, CNC routers typically have larger work areas, allowing for processing bigger pieces of material in one go, thus enhancing productivity.

While CNC Routers are generally faster and more versatile than Swiss Lathes, they may not match the precision of a Swiss Lathe for extremely detailed or small-scale work. However, for most applications requiring speed, versatility, and considerable accuracy, a CNC Router is often the more productive option.

How to Choose the Right Machine for Your Productivity Needs

When deciding which machine is better in terms of productivity, consider the nature of the work you’ll be doing. Suppose your production requires the creation of small, highly intricate parts with tight tolerances. In that case, the CNC Swiss Lathe’s ability to deliver precision and consistency at high volumes makes it the superior choice. However, the CNC Router may offer better overall productivity if your needs lean towards versatility and faster production times.

Conclusion

Choosing between a CNC Swiss Lathe and a CNC Router ultimately depends on your manufacturing needs. The CNC Swiss Lathe produces small, intricate parts with unmatched precision. However, this precision comes at a higher cost and requires specialized training. On the other hand, the CNC Router offers greater versatility and speed, making it the better option for handling larger workpieces and various materials. Your choice between the two should be guided by whether precision or versatility better serves your production needs.

You can transform your manufacturing capabilities with Zintilon’s CNC precision machining services. Whether you’re seeking precision with a CNC Swiss Lathe or versatility with a CNC Router, we have the expertise to guide you in making the best investment for your business. Don’t wait; reach out today and discover how we can help you achieve superior productivity.