Benefits of Acu-Rite Parts

In the evolving world of CNC machining, the quality of the parts utilized can profoundly impact overall performance and productivity. Integrating Acu Rite parts into your machinery is a proactive step towards boosting efficiency. These parts are celebrated for their exceptional durability and precision. Employing top-tier components like Acu-Rite ensures that your CNC machines run smoothly, with reduced downtime and fewer maintenance interruptions, allowing you to focus more on production than repairs.

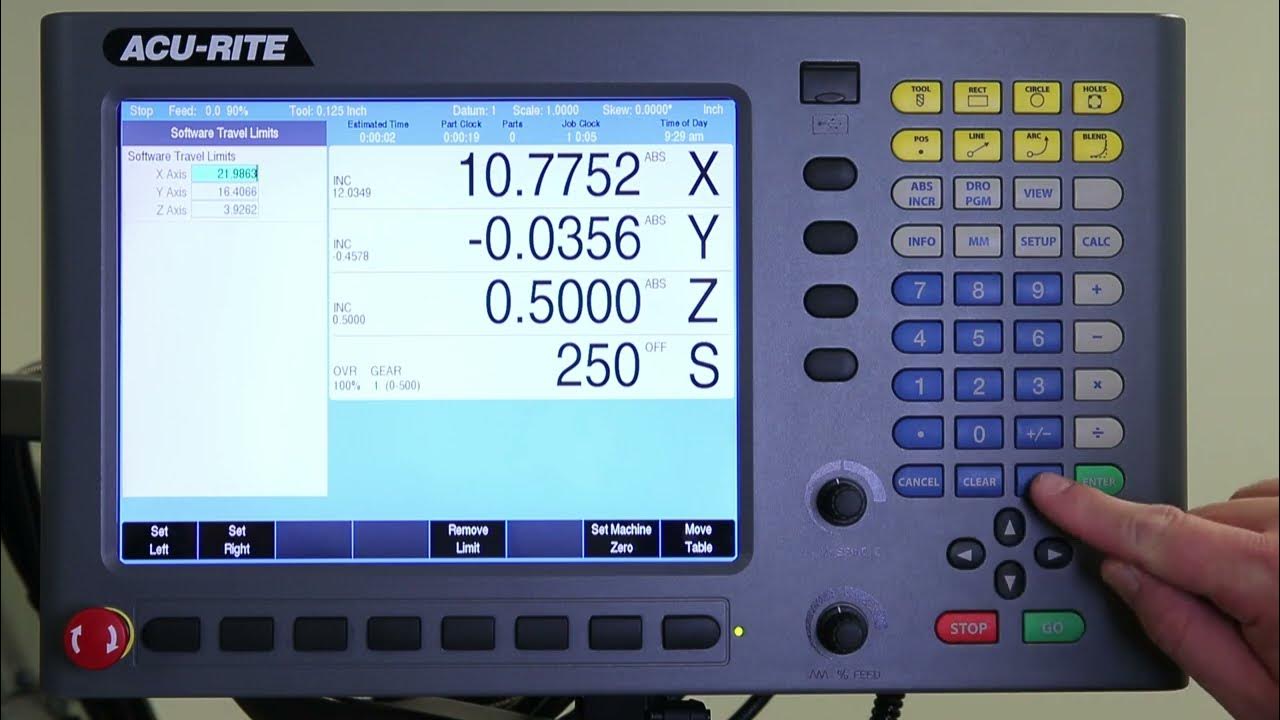

Moreover, Acu-Rite parts bring advanced technological benefits. For instance, their digital readouts, scales, and encoders are designed with the latest innovations to enable high-precision machining. This technological edge is not just about fancy features—it translates directly into real-world benefits such as smoother operations, fewer errors, and higher-quality output. In industries where accuracy is paramount, the performance enhancements provided by these parts are invaluable.

Key Considerations When Choosing Acu-Rite Parts

Compatibility

One vital factor when selecting Acu-Rite parts is compatibility with your existing CNC machinery. Compatibility ensures seamless integration, which is essential for maintaining uninterrupted production. Before purchasing, verify that the parts conform to the specifications of your existing equipment. This preliminary check can save considerable time and expense associated with returns or modifications.

Accuracy

The next critical factor is accuracy. Precision components are indispensable in CNC machining, where even a slight deviation can result in flawed products. Acu-Rite parts are engineered to meet high accuracy standards, ensuring that your millings and cuttings are executed precisely. This precision is crucial, especially when working on complex projects that demand tight tolerances and flawless finishes.

Longevity

Durability is another significant consideration. CNC parts undergo substantial wear and tear during operations. Parts not built to last can lead to frequent breakdowns, disrupting production schedules and increasing operational costs. Investing in durable Acu-Rite parts means opting for components that will endure heavy use and have a longer operational lifespan, reducing the frequency and cost of replacements and maintenance.

Support

Technical support and documentation are essential for the smooth operation of CNC components. Reliable support can make a difference in troubleshooting and swiftly resolving issues. Acu-Rite provides comprehensive manuals and robust customer support, ensuring you have all the necessary resources to install, operate, and maintain your parts efficiently. This level of support is especially beneficial when integrating new components into your system.

Installation and Maintenance Tips

Proper installation and regular maintenance can significantly enhance the longevity and performance of Acu-Rite parts. Following these tips can help keep your CNC machinery in top condition:

- Read the Manual: The installation manual provided by Acu-Rite contains detailed, step-by-step instructions. Adhering to these guidelines is crucial for correct installation and optimal performance. Ignoring these instructions can lead to improper setup, potentially damaging the parts and machinery.

- Regular Inspections: Routine inspections are a proactive way to identify and address issues early. Conducting regular check-ups can prevent minor problems from becoming costly repairs. During inspections, pay attention to wear signs and lubrication levels and ensure all components function correctly.

- Use Authorized Dealers: Sourcing parts from authorized dealers ensures authenticity and quality. Purchasing from authorized sources guarantees genuine Acu-Rite parts with proper support and warranty coverage. Using counterfeit parts can compromise the performance and reliability of your CNC machinery.