Injection molding is a vital technique that increases cost efficiency, speed, and product quality. It offers a reliable solution for manufacturers looking to mass-produce their products. It also comes with massive benefits like reducing time to market and costs. Durability and cost efficiency are critical for manufacturers. Creating quality products at reasonable prices while spending less time on every dispatch keeps your clients happy. Mass production of plastic parts is possible with injection mold design. Here’s an outlook on injection mold design for high-volume production and the best practices for durability and efficiency.

Understanding Injection Molding and Its Challenges

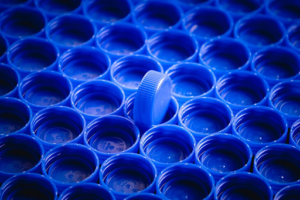

The injection molding process makes it possible to produce identical plastic parts cost-effectively and efficiently. The process starts with quickly injecting molten plastic into a molding cavity. The plastic cools and solidifies forming desired shapes. The process is automated to ensure rapid production and that the parts created are identical. Large productions range from a thousand to 1 million parts produced annually. Manufacturers face several challenges during production like wear and tear, cycle time, and accuracy. Producing large batches of parts requires more time and resources. You want solutions that cut costs and minimize losses due to product deficits in every batch. Injection mold design ensures uniformity of product and maintains quality.

Designing for Durability: Key Consideration

Durability entails the ability to withstand conditions of operation without needing maintenance. Different plastic materials have varying degrees of flexibility, strength, durability, and heat resistance. When picking the right material, you determine the quality of the finished product. Strong resin materials like Acrylonitrile Butadiene Styrene ABS, handle heat well and are suitable for creating automotive parts, household items, and acrylics.

Mold maintenance is yet another factor to consider. You should have a plan for mold maintenance. Good maintenance practices keep molds in great shape reducing inconsistencies during production. Your cooling channels should be in the right place to reduce warping. Cooling channels and surface finishes need care and maintenance. Regular maintenance ensures your production plant lasts long and gives you quality output. Good mold design ensures an optimized resin flow for uniformity. It also ensures zero overflows to protect the surfaces.

The mold designs you choose should optimize your product and enhance durability. Mold designs should be practical. You should utilize designers who understand the intricacies of manufacturing. Experienced designers utilize computer-aided designs that suit your production needs. The designs go beyond the shapes and sizes of the product to incorporate other needs like uniformity.

Maximizing Efficiency in High-Volume Production

You can maximize efficiency in a high-volume production. Certain aspects like the cooling channel design determine the output. You also regulate cooling, venting, and gating processes during production. The cooling time and the cooling temperature also impact the finished product. When automating and optimizing the processes, ensure that you give ample time to a part spent inside a mold before ejection. To optimize cycle time, you should ensure that the designs have uniform wall thickness and avoid complex geometries. Ultimately, these will reduce the cooling time.

Automation and robotics are your allies in mass production. Manufacturing experts create systems that ensure the manufacturing processes are smooth and effective. Every little process is automated to enhance efficiency. Automation also helps reduce wastage and cuts cycle time. Robotics, on the other hand, ensures that you get beyond human capabilities to handle manual tasks during production. Robotics arms remove the products from the molds once they cool off. They can also load plastic pallets into the injection molding machine.

Production defects waste your time and money. You should invest in precise mold designs to reduce the risk of defects during the manufacturing process. You can outsource mold designing to professionals at China Injection Mold. They have everything you need to build the right injection molds. Good designs work well with your choice of resin material to give a quality product.

Best Practices for Cost Control and Long-Term Performance

You may feel overwhelmed with initial mold design costs and the investment it takes to start your plastic manufacturing business. While cheap resins are easy and more affordable to manufacture, they compromise product quality. Your customers will not enjoy the products. Initial investments may mean long-term gains when used strategically. Quality mold designs reduce cycle time, cut waste, and serve you longer. They also cut maintenance costs.

Proper design is crucial to optimizing the whole production process. While you will spend money on proper designs, they set the pace for your business. Problems like machine breakdown, low-quality output, and product defects will force you to dig deeper into your pocket. Proper molds produce durable products that your customers will swear by, making your venture profitable. The proper design molds save energy and increase output. High-volume injection molding increases production while maintaining quality.

Put in place improvement strategies for improving mold performance over time. Cleaning molds can help them last longer. Immersing molds in a strong solvent can help repair the damage over time reducing wear and tear. Lubricating mold components also enhances mold performance. Schedule quality control checks to ensure your molds are working well. The checks should include testing that the molds are in great shape. Regular inspection and repairs ensure that no breakdown catches you off guard and interrupts the production process. Lastly, replace broken and damaged molds regularly. When molds break down beyond repair, get replacements to avoid compromising the product. That will save you the headache of batch recalls.

Conclusion

No doubt mold designs are the heart of plastic manufacturing processes. You should ensure your injection molds are efficient and outstanding. Injection molds should be durable. The designs should have the right wall thickness and use suitable material to support the process. The injection molds should also utilize simple geometric angles to ease the manufacturing process.

Effective mold design can drive high-volume production success. The best mold designs are efficient. They also have high turnover rates of quality products increasing production. Investing in effective mold designs increases your company’s profitability, reduces production stress, and fosters great customer relations.